Contact Details:

Danfoss (Pty) Ltd

20 Woodlands Drive

Building 14, Woodlands

Woodlands

Woodmead

Johannesburg

2191

South Africa

Tel: +27 (0)10 500 3333

Fax: +27 11 803 8244

Send Enquiry | Company Information

Danfoss is ready to meet global water challenges

Product News Thursday, March 15, 2018: Danfoss (Pty) Ltd

Water scarcity and climate change are among the top 5 global risks, according to the World Economic Forum; pioneering solutions that can help meet both challenges are ready to be deployed.

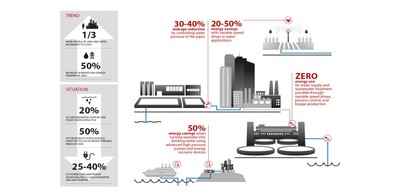

As the world population rises and people pursue higher standards of living, more water is needed in homes and for production of food and products. By 2050, the United Nations projects global water demand to increase by 55 percent. However, fresh water supplies are limited, and groundwater, which is the source of drinking water for at least half of the global population, is used much faster than it is replenished. In just 10 years, 50 percent of the global population is expected to live in water-stressed areas. The increasing demand for water also leads to growing energy consumption, which affects the climate.

Danfoss, a world-leading supplier of technologies for infrastructure, food supply, energy and climate, has solutions which help countries and municipalities worldwide save water and energy in water supply, wastewater treatment and irrigation of farming areas. For example, Danfoss has supported Denmark in becoming one of the pioneering countries in the water and energy field. The country has grown its economy by 80 percent since 1980, while reducing water consumption by nearly 40 percent and keeping energy use at the same level. Structured water management and innovative technologies have contributed to this decoupling of economic growth, water consumption and energy use.

In municipalities, water and wastewater facilities account for the largest consumption of electricity, typically 25–40 percent of the local authorities’ total power use. In the Danish city of Aarhus, a local water company has managed to transform a wastewater facility from being just a wastewater plant into also functioning as a combined heat and power plant, delivering an energy surplus. The plant produces 90 percent more energy than it consumes. The excess heat is led into the district heating system in the city, thereby reducing its carbon footprint. This is feasible thanks to advanced process optimization and by using more than 140 variable speed drives from Danfoss as control handles on almost all rotating equipment. Done optimally, this also creates the maximum amount of sludge and carbon. In a digester, it is transformed into gas used for both electricity and heat production.

Mads Warming, global director of water and wastewater in Danfoss, says: “It’s a ground-breaking innovation case that shows what is possible within advanced process control. As far as we know, no other country has managed to get a water treatment plant to actually produce so much additional energy based on normal household wastewater. Scaled up, it means that the huge energy consumption from water and wastewater facilities could be avoided, turning the single largest electricity consumer in municipalities into an energy-neutral party.”

The vision for Aarhus Water is also to extend energy generation to achieve so much surplus energy from its wastewater treatment plants that it can meet the energy requirement of the city’s total water and wastewater cycles. This goal is expected to be reached in 2016.

The case has attracted attention in cities worldwide. At the beginning of 2015, Aarhus Water signed a cooperation agreement with the water supply company in Chicago (MWRD), which faces the same kind of challenges and pursues the same goals. With the agreement, they have started to share knowledge about water technologies and climate adaption and energy neutrality, in particular.

If the Aarhus case were replicated on a global scale, the energy saved would be equivalent to the current electricity production from all renewable energy sources combined (excluding hydropower).

Globally, focus on the high energy consumption in the water and wastewater cycles is also increasing, and local regulations are starting to further the use of energy-efficient solutions. One example is the EU’s Ecodesign Directive. In the US, the Department of Energy is also proposing minimum efficiency regulations for clean water pumps. Regulations like these are necessary to speed up the realization of the enormous potential.

Reducing water leaks is critical to sustainable water

When it comes to water supply and irrigation of farming areas, another huge potential is the reduction of water losses in pipework due to leakage. According to the international consultancy firm McKinsey, $167 bn is wasted every year due to leakage in cities around the world. The United Nations highlights that leakage rates of 50 percent are not uncommon in urban distribution systems. However, leakages can typically be reduced by 30–40 percent using technologies like variable speed drives and sensors, which control the pressure in the pipes to avoid water flooding out of holes. At the same time, the drives typically save 20–50 percent energy.

Mads Warming says: “The global water and climate challenges are a difficult code to crack, but the solutions that can meet them are ready and we also see that focus on leakage reduction and energy efficiency is increasing. Last year, we experienced double-digit growth in our water and wastewater business, and the positive trend continues.”

Besides saving water and energy in countries and municipalities, Danfoss is also helping produce drinking water in remote locations like islands, drilling platforms and cruise ships. Here, Danfoss takes part in efficiently turning seawater into drinking water using advanced high pressure pumps and energy recovery devices for desalination systems. The Danfoss solutions save up to 50 percent energy, which is important for the deployment, because at least 70 percent of the total costs in desalination systems are related to energy use.

Mads Warming says: “Earlier this year, the World Economic Forum ranked water crisis and failure of climate change adaption among the top five global risks and encouraged decision-makers worldwide to take collective action to address them. And there is no reason to wait. Well-proven solutions, which meet the water and climate challenges, are ready and they are paid back fast.”

“According to the US Department of Energy, critical processes in water, wastewater and irrigation jointly use more than 55 billion kilowatt-hours (kWh) each year,” explains John Masters, vice president – sales, water, Danfoss North America. “For US municipalities, rising energy costs play a significant role in water and wastewater treatment services. At the same time, a plant’s ability to treat, use and deliver water efficiently – reducing water loss – also has a direct impact on the plant’s energy consumption and bottom line. Danfoss variable speed drives, however, can address the interdependency of water and energy by providing intelligent pump control to match the motor’s workload more precisely and assisting with constant pressure control schemes that reduce water loss through flow compensation. Variable speed technology could save municipalities as much as three to 10 billion kWh each year.”

This article was also published on the Empowering Pumps blog.